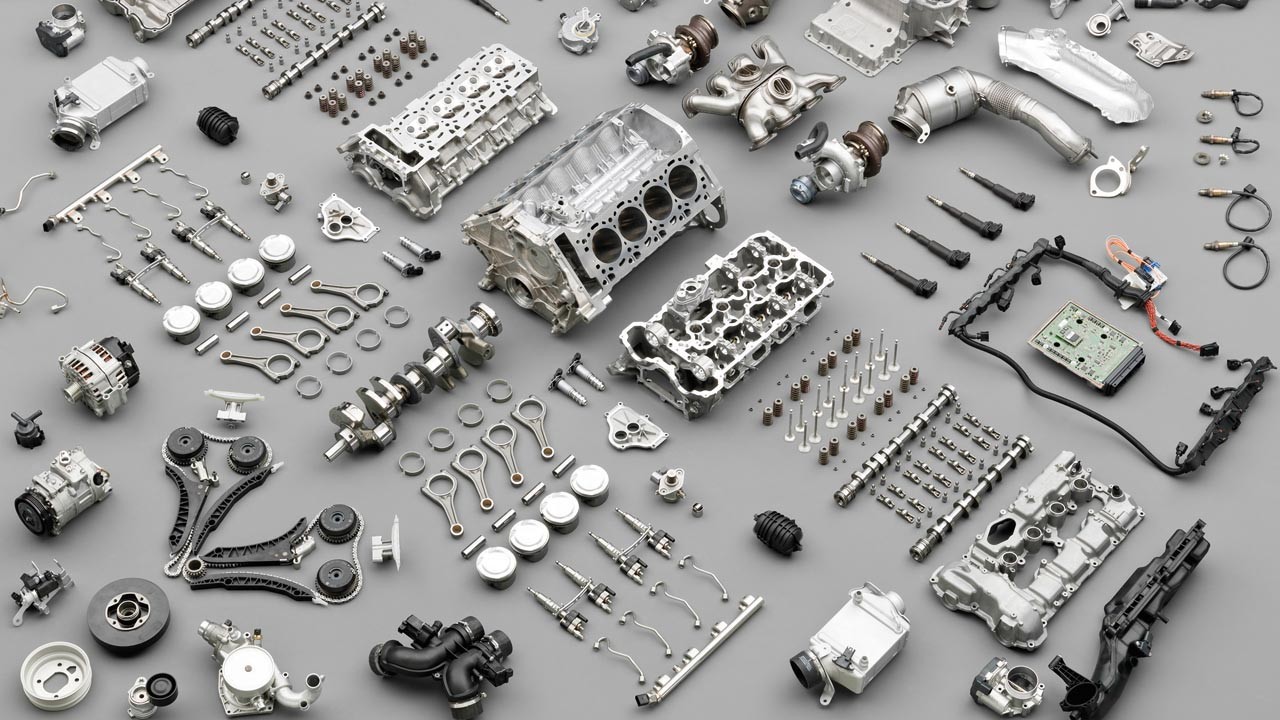

Installing a press in sleeve is bit complicated as compared to ordinary sleeves. They need precision and care, and following we are giving you a quick guide. This guide will ensure a press-in sleeve easily slides on the cylinder.

Installing a Press-in Sleeve

Installing a press-in sleeve is an effective way to get more use out of your old block. Cylinder damage can be somewhat reversed by installing a high-end sleeve. Its affordable as compared replacing cylinders, or block.

Dive In

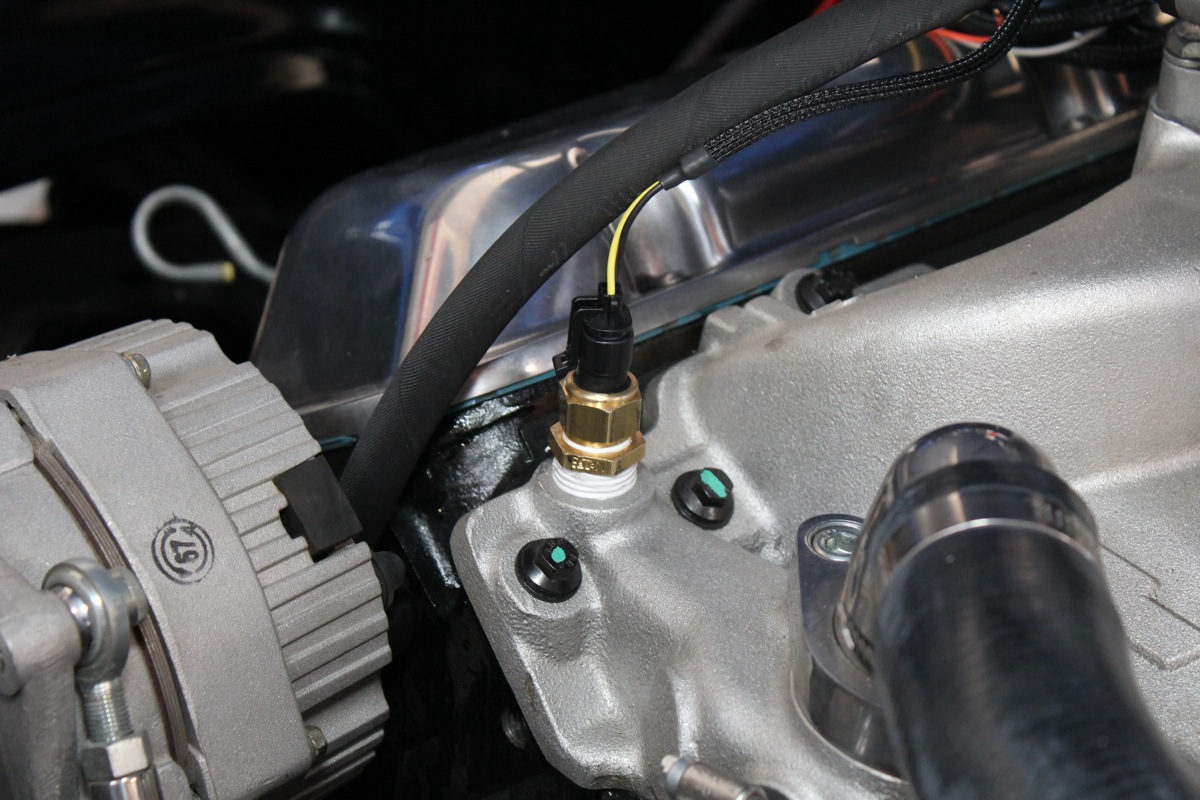

You have to measure the High Performance Cylinder Sleeve to calculate the press and inference fit. Be careful because there can be some distortion, but you can conform it to fit properly. You can press the sleeve to refrigerate, and shrink it a bit. You can also stick the liner into a freezer once you have measured it. There are many facts that effect the press you use, these are a few them:

- Where the damaged occur, and is it a crack or proper hole

- Extent of damage, is there are big chunk missing because the damage has occurred under stress

- Material and strength of your engine block

- Were the cylinders bored, or not

- Don’t step the bottom of cylinder

You need to apply the sleeve retainer complaint, and press the drive sleeve carefully into block. You have to ensure the sleeve has slipped all the way down to the bottom. If there is any excess sleeve material hanging from the ledge, you have to trim it down.

Finish the Job

Take a sharp blade, and remove any protrusion which leads to gasket issues. If you don’t want to mill the block, you can stone top deck as the finishing touch you need to use a hard griddle stone, and soft knife to sharpen. You may have to chamfer the inside of sleeve.

Safety is Mark’s top priority. His blog isn’t just advice; it’s a guardian angel for drivers. Stay informed about the latest safety features, and drive with confidence, knowing Mark has your back.